I think it was Play School that gave me a fascination for factories. I’ll never forget “going through the round window” and seeing all these production lines making things. Weird, I know, but that’s the kind of girl I am. Anyway, here’s an article on the manufacture of fully-fashioned stockings that the similarly afflicted may enjoy.

In the 1940s and 1950s nylon stockings were fully-fashioned, as opposed to most modern stockings, which are ‘one-size’. Fully fashioned stockings were tailored to the shape of the leg, and were seamed up the back. The seam was an essential part of the stocking’s construction, as it held it together. This is unlike modern so-called ‘seamed’ stockings, which are woven into a tube shape and which have a purely decorative ‘seam’. Fully fashioned stockings were made from silky non-stretch, gossamer nylon fabric (so they couldn’t be ‘one-size’). In other words, take the seam out of a fully-fashioned stocking and it will be un-wearable but a modern stocking could still be worn.

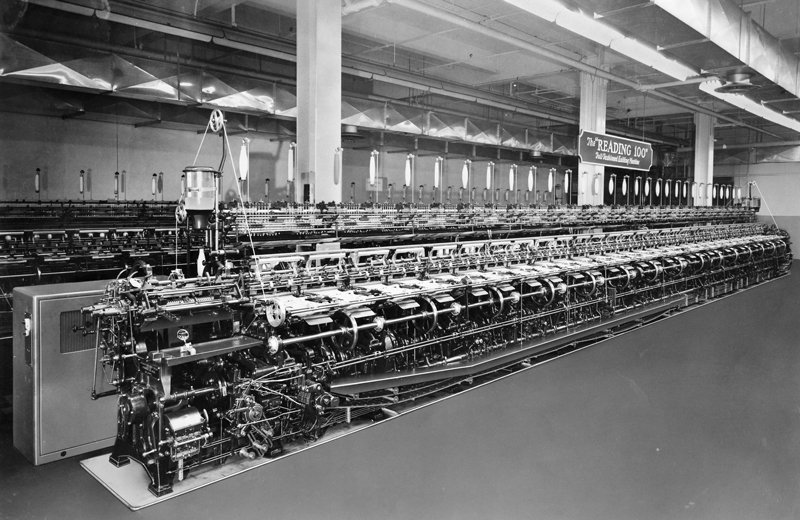

Fully fashioned nylons are knitted on mills. They are still manufactured today by a small number of companies, who tend to use either genuine, 1950s machinery, or replicas of it. Stocking mills are huge machines – some are up to 60 feet long and 12 tons in weight. With 16,000 needles per machine they need constant attention and take one hour to produce only 30 legs. After manufacture each stocking is seamed, one at a time. Once the stocking has been knitted, the seam is added, giving the stocking its classic shape and fit. The ‘finishing loop’ at the top back of the stocking is also a result of the finishing process, and is created because the seaming machinist has to finish the seam by turning the stocking top (called ‘the welt’) in a circle. The finishing loop identifies a true fully-fashioned nylon.

Stockings are usually manufactured white, then dyed different colors. After this, they’re ‘boarded’ where each stocking is pulled over a flat wooden or metal leg and steamed. This tightens the knit, defines the leg shape and removes creases. Then each stocking is checked for size to ensure pairs match. Quality control for faults can mean 40% of production can be lost. Often, the old machinery can only churn out 15 pairs of stockings per hour, so it’s obviously not a cost effective way of manufacturing. This means that fully fashioned stockings are now a rarity, although thankfully you can still buy them.